Infusion Process

These products are specially designed to transport liquid resin from the barrel into the sealed system, help distribute the resin uniformly underneath the vacuum bag and restrict the resin flow. They protect the vacuum hoses and pumps, help control the volumes of resin pulled into the part and offer both reusable and disposable methods for resin distribution.

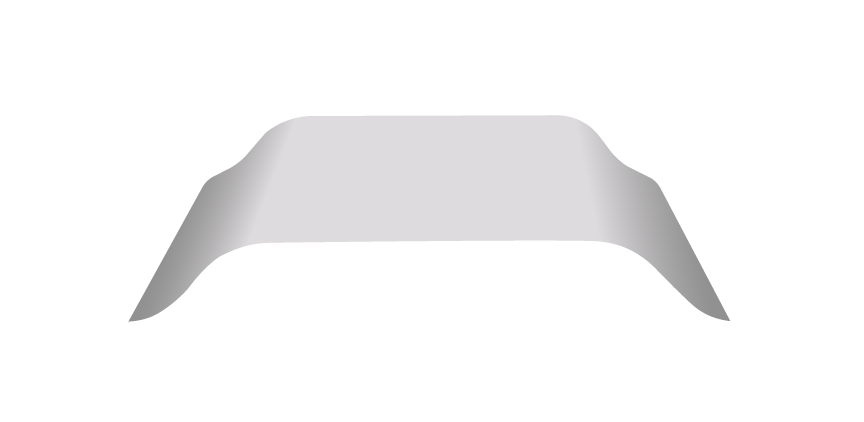

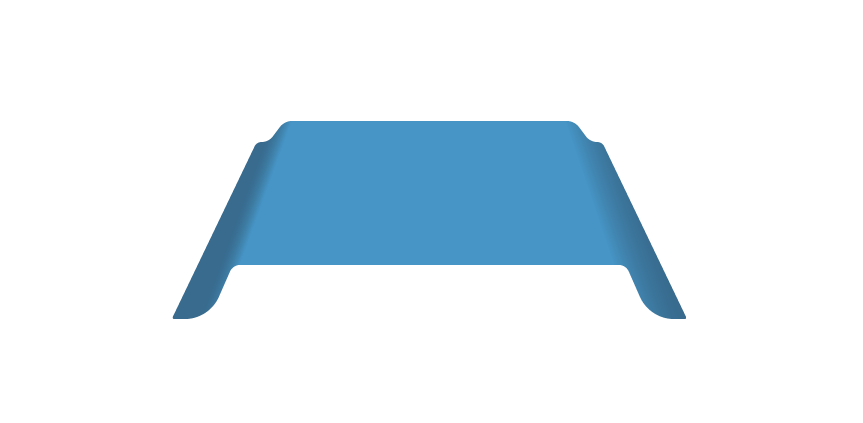

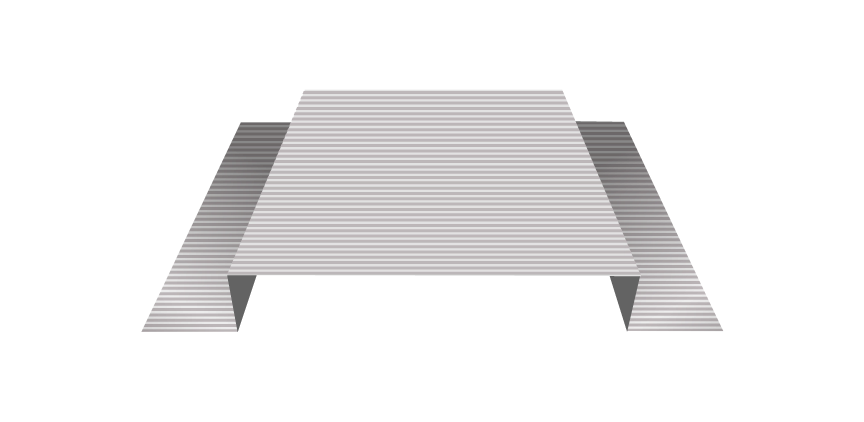

The infusion process is a manufacturing technique used in open tool composite production. Reinforcement materials are laid up dry and several consumable products are placed on top; usually a peel ply, release film, flow media and vacuum bagging film (see diagram below) then vacuum is applied for part consolidation.

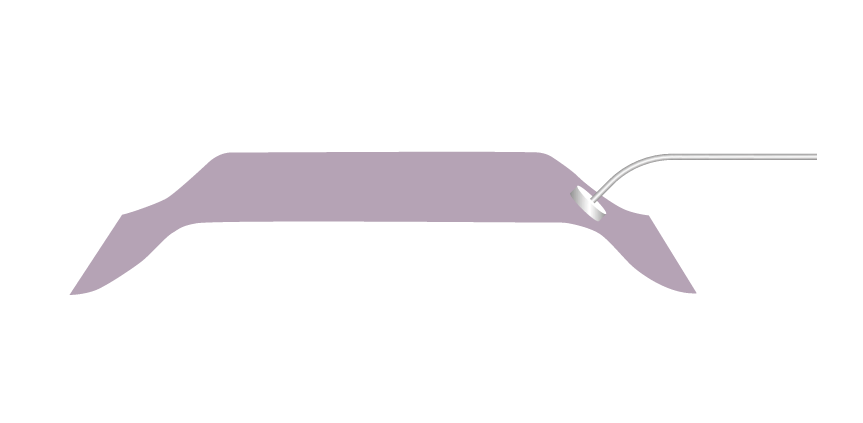

When the tool is closed (sealed by a vacuum bag) and all the air has been evacuated from the dry lay-up, the resin is transferred through the bag into the laminate, distributed by a channel or lining/mesh.

Under pressure, the resin, allowed to breathe in an open vessel, is fed through the vacuum bag using plastic tubing and distributed over the entire surface of the reinforcement material utilizing a combination of porous channels and a distribution medium/mesh.

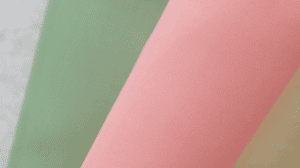

Vacuum Bagging Film

Release Film

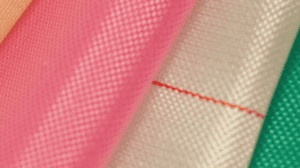

Peel Ply/Release Fabric

Composite Material

Breather Fabric or

Infusion Medium/Mesh

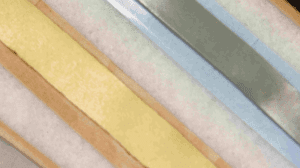

Sealant Tape

PTFE Tool Release

Mould