Release Films

Films For a Wide Range of Composite Applications

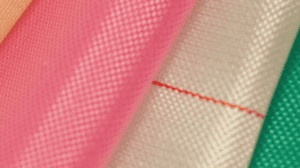

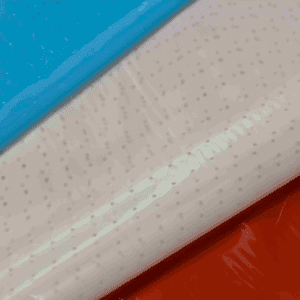

Aerovac Release films allow for the removal from the composite part of other process materials such as breather fabric and flow media. A wide variety of available perforation patterns, including pin-prick, hot needle and punched, allow manufacturers to tightly control resin bleed in various composite manufacturing processes.

They are high quality, accessible, easy to customize and supported by experienced technical experts. From global facility locations, Aerovac’s research and development capability is focused on unique customer solutions. Whether it’s humidity resistance or tailored formatting to reduce labor costs, your needs are our priority.

Aerovac Release Films are available through Composites One in North America, or globally through the Aerovac Distributor Network.

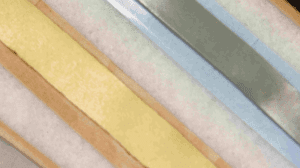

RELEASE Film Product List

For more detailed information on each product, fill out the form below to download the respective Technical Data Sheets.

Product

Temp. °F(°C)

Description

A2200

248° (120°)

Clear orange, modified PE (Polyethylene) polymer film ideal for use in resin infusion and compatible with epoxy, polyester and vinylester resins up to 248°F (120°C).

A2000

302° (150°)

Red, modified, high elongation PP (Polypropylene) polymer film with excellent release characteristics and compatibility with all commonly used resin systems up to 302°F (150°C).

A2300

302° (150°)

Perforated and ideal for medium temperature processes. It is a cast co-extruded polyolefin based film specially developed for release application in infusion and prepreg process.

A2400

248° (120°)

Perforated and ideal for low temperature processes. It is a polyolefin film specially developed for release application in infusion process with a max. use temperature of 120°C/248°F.

A2500

400° (204°)

Pink, modified PMP (Polymethylpentene) polymer film, with excellent release characteristics, suitable for a wide range of parting film applications up to 400°F (204°C).

VAC-PAK® E2760

250° (121°)

Red-tinted, modified high elongation polymer film used in a range of release film applications up to 250°F (121°C).

VAC-PAK® E3760

400° (204°)

Clear/white release film, qualified for use in multiple aerospace composite processing applications up to 400°F (204°C).

VAC-PAK® E4760

400° (204°)

Clear/blue, modified polymer film with excellent release properties ideal for use with mild contours and flat panel applications up to 400°F (204°C).

VAC-PAK® E7760W

400° (204°)

White high modulus film suitable for use with all commonly used resin systems up to 400°F (204°C). May be a suitable alternative to other, higher elongation and PVF films. Excellent film for mildly contoured or flat parts, as it lies flat and smooth with few wrinkling issues.

A5000

500° (260°)

Red, white or violet FEP (Fluorinated Ethylene Propylene) film with high elongation and excellent release characteristics up to 500°F (260°C), approved by numerous OEMs

VAC-PAK® A6200/A6200M & A6000

503° (262°)

High temperature, tough fluoropolymer release films with excellent release characteristics combined with high elongation. Suitable for use with all commonly used resin systems. Available perforated or non-perforated.

MR-FILM

350° (177°)

Red/beige PTFE (polytetrafluoroethylene) film with high elongation and excellent yield up to 600°F (315°C), which releases well from even the most aggressive resin systems.

P720X

200° (93°)

White, matte finish film with high modulus and low elongation providing a flat contact surface that is compatible with most commonly used resin systems and adhesives up to 200°F (93°C).