Products

Home > Products

Composite Process Materials

Aerovac Process Materials

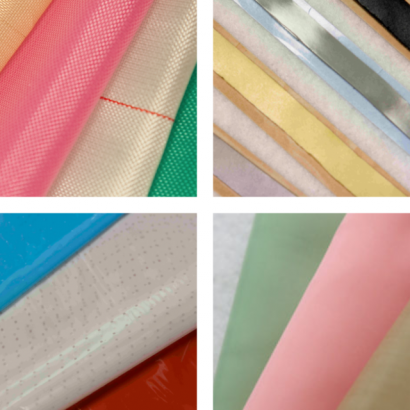

Composites production molding requires a range of process materials to make quality parts. These vacuum bagging and process materials are essential components of the manufacturing system. Aerovac process materials for composite manufacturing include bagging films, release films, breather fabrics, peel plies, release fabrics, and sealant tapes.

At Aerovac Composites One, we make it easy for customers to globally source, safely transport, locally store, and efficiently utilize high quality process materials so they can focus on engineering end-products, growing revenue, and delivering results to their bottom line.

Essential Composite Manufacturing Products

Most Aerovac process material products fall into one of six categories. Please click on a category below for more information.

BAGGING FILMS

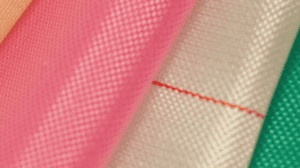

PEEL PLY

RELEASE FILMS

RELEASE FABRIC

BREATHER FABRIC

SEALANT TAPE

Additional Process Materials from Aerovac

Click here to see our other categories of process materials for composite manufacturing which include:

• Tubing

• Spiral wrap

• Connectors

• Resin feed lines

• Vacuum lines

• Vacuum pumps

• Catch pots

• Clamps

• Leak detectors

• Gauges

Markets Served by Aerovac

Our expertise in composites and process materials serve a wide range of industries, including aerospace, laminated glass, marine, motorsports, and wind energy. We also work with customers across numerous new growing markets, as well.

Innovative. Dependable. Results.

At Aerovac Composites One we are focused on our customers. We are focused on vacuum bagging and consumable process materials. Most importantly, we are focused on results.

We are 100% FOCUSED ON MANUFACTURING AND DELIVERING HIGH QUALITY VACUUM BAGGING AND CONSUMABLE MATERIALS that are stored locally, consistently delivered on-time, competitively priced, and supported by a team of 100+ technical product specialists located across the globe.

We are 100% COMMITTED TO CUSTOMER SATISFACTION, and our dedicated team of pre-sale product selection experts and post-sale technical application experts consistently ranks as the most dependable process and customer service and technical support resources in the process materials industry – with additional backing from Composites One, the global leader in composite materials.

We make SIGNIFICANT – AND ON-GOING – INVESTMENTS in new product development, process automation, improved cost controls, and next-generation supply chain solutions to drive lower MLQ, shorter lead times, and total delivery assurance.

We are fully dedicated to DELIVERING RESULTS THAT MAKE IT EASY for customers to achieve their manufacturing goals, and we ensure no customer should have to make trade-offs in their product quality, customer service, technical acumen, or supply chain logistics.

If you want to learn what makes us the leading composite specialists serving the marketplace today, get in touch with us to find out about our reliable technical support, shop our selection, and inquire about how to place your order. Please complete the form below.