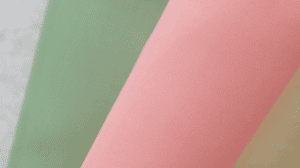

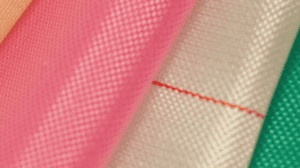

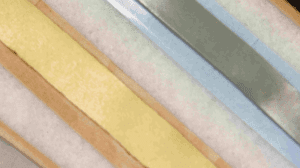

Release Fabric

Nylon, glass and polyester woven fabrics with silicone, fluorocarbon, and PTFE (Polytetrafluoroethylene) coatings

Resin and cure temperature requirements vary. To satisfy specific application requirements, Aerovac makes light to heavyweight woven fabrics in nylon, glass and polyester, with silicone and fluoropolymer coatings. Release fabric is available in standard formats, slit widths and cut to shape.

Aerovac Release Fabrics are available through Composites One in North America or through Aerovac’s Distribution Network globally.

Release Fabric Product List

For more detailed information about each product, fill out the form below the product table to download the technical data sheet PDFs.

Product

Weight/Length

Description

200TFP

Range available (Download technical data sheet for data)

Beige, porous PTFE-coated plain weave fiberglass cloth, resistant to all solvents, adhesives and resin systems normally encountered in composite and metal-bond manufacture. Works up to 550°F (288°C).

B4444

1.7oz/yd (60g/m)

Green, lightweight nylon fabric, coated with heat cured silicone release solution to aid removal from the cured laminate working up to 400°F (204°C).

A8888

2.3oz/yd (80g/m)

Green, medium weight nylon fabric, coated with heat cured silicone release solution to aid removal from the cured laminate, working up to 400°F (204°C).

BR100

1.7oz/yd (60g/m)

Pink, lightweight nylon fabric, coated with a heat stabilized fluorocarbon release solution. The fabric imparts a fine weave finish and controls resin bleed closely and strips easily from resin rich composites, operating at temperatures up to 400°F (204°C).

200TFNP

3.2oz/yd (108g/m)

Non-porous, PTFE-coated, plain weave fiberglass cloth which is designed as a release fabric which will prevent resin from bleeding through the release fabric and into the breather fabric. Imparts a gloss finish to laminate surface and works up to 550°F (288 °C).

FF03A

4.3oz/yd (145g/m)

Non-porous, PTFE-coated, plain weave fiberglass cloth which is designed as a release fabric which will prevent resin from bleeding through the release fabric and into the breather fabric. Imparts a gloss finish to laminate surface and works up to 550°F (288°C).

FF05A

8oz/yd (270g/m)

Non-porous, PTFE-coated, plain weave fiberglass cloth which is designed as a release fabric which will prevent resin from bleeding through the release fabric and into the breather fabric. Imparts a gloss finish to laminate surface and works up to 550°F (288°C).

FF10A

14.7oz/yd (500g/m)

Non-porous, PTFE-coated, plain weave fiberglass cloth which is designed as a release fabric which will prevent resin from bleeding through the release fabric and into the breather fabric. Imparts a gloss finish to laminate surface and works up to 550°F (288°C).

200TFP-1

1.4oz/yd (46g/m)

Tan colored, lightweight, PTFE coated glass fabric which allows excess resin, volatiles and trapped air to bleed through and be absorbed into the breather, or vented away from the assembly, operating in temperatures up to 608°F (320°C).

FF03PM

1.8oz/yd (63g/m)

Brown, lightweight, porous, PTFE coated glass fabric, which is ideal for use on flat or single curvature moldings in extreme temperature and pressure conditions, up to 608°F (320°C).

FF05PM

3.8oz/yd (130g/m)

Brown, medium weight, porous, PTFE coated glass fabric, which is ideal for use on flat or single curvature moldings in extreme temperature and pressure conditions, up to 608°F (320°C).

FF10PM

6.8oz/yd (230g/m)

Brown, heavyweight, porous, PTFE coated glass fabric, which is ideal for use on flat or single curvature moldings in extreme temperature and pressure conditions, up to 608°F (320°C).

Please check the box next to the Release Fabric products you are interested in and fill out the form to download the Technical Data Sheet PDFs. The download will happen automatically upon submission.

Frequently Asked Questions

How do I choose the right Aerovac release fabric for my application?

When choosing a release film or fabric, you need to think about the resin type you’re using, your application’s temperature requirements, and whether your fabric needs to be porous or non-porous. Refer to each product’s technical data sheets to get detailed specifications.

What is the highest operating temperature for Aerovac release fabrics?

The FF03PM, FF05PM, and FF10PM series of fabrics can withstand temperatures up to 608 degrees Fahrenheit (320 degrees Celsius).

What is the purpose of the coating on Aerovac fabrics?

Specialized coatings including PTFE, silicone, and fluorocarbon enhance the release properties, improve the fabric’s durability, and prevent resin adhesion.

What product is best for creating a gloss finish on laminates?

Non-porous fabrics such as FF03A, FF05A, or FF10A when properly used, can help achieve a gloss finish on your finished products.

Are there lightweight options available for delicate moldings?

Yes, lightweight fabrics such as 200TFP-1 and FF03PM are designed specifically for use in especially delicate applications.

Where can I purchase Aerovac release fabrics?

Aerovac release fabrics are available through Composites One in North America as well as globally, including through Aerovac authorized distributors.

Can I order custom sizes or shapes of release fabrics?

Yes, Aerovac release fabrics are available in standard formats as well as slit widths and cut-to-shape options.

How do I download technical data sheets for these products?

Just select the product you’re interested in from the list below, fill out the form on the page, and your technical data sheets will download automatically upon submission.