Laminated Glass

Aerovac Process Materials Meet the Needs for this Growing Market

Serving the rapidly growing laminated glass markets, Aerovac is strategically positioned to meet the needs of our customers.

- Full product line availability

- Customized kits

- Technical plant audits focused on finding cost reduction opportunities

- Local and logistics in North America

- Dependable service

Why Aerovac for Laminated Glass?

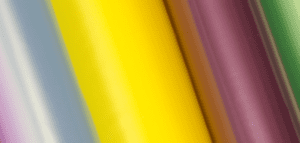

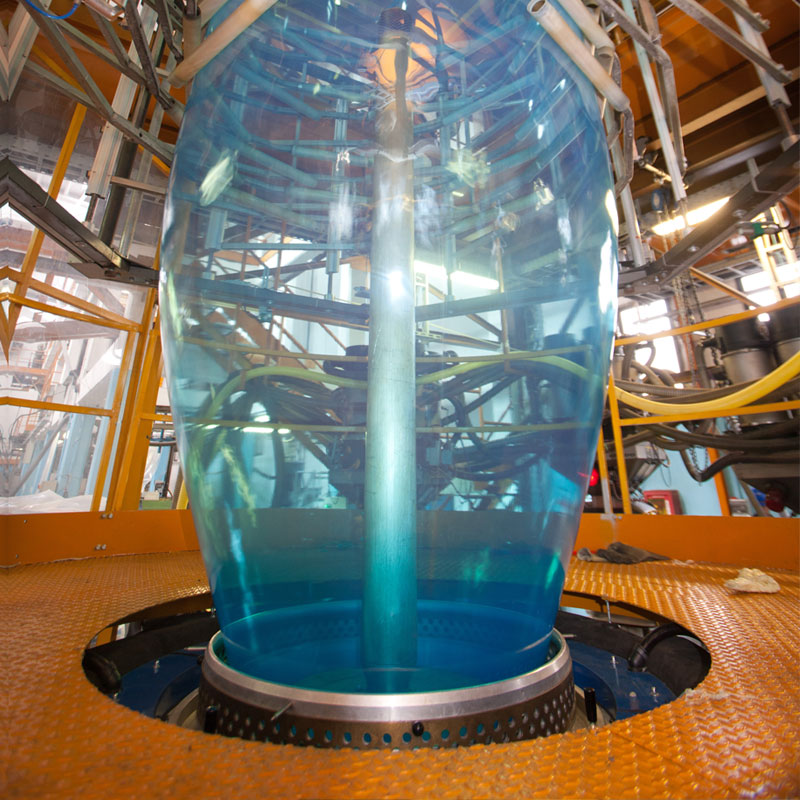

Due to large applications across a host of end users, the glass lamination market is growing rapidly. Laminated glass is popular because of its strength and safety features including hurricane and impact resistance, protection against forced entry, sound reduction, bullet resistance, and earthquake resistance. This type of glass is created in an autoclave or in vacuum assisted ovens in a process similar to aerospace composite processes demanding high quality FOD free products. Key applications for laminated glass are automobile windshields, gas stations, residential buildings, bank and ATM booth security, jewelry shops, and more. Aerovac offers a complete line of process materials for these applications including vacuum bags, peel ply, breather, sealant tape, vacuum breach units, and other key products.