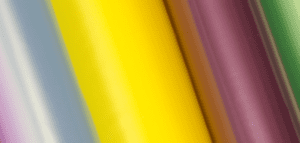

Bagging Films

Bagging Film for Closed Molding, Vacuum Bagging and Out-of-Autoclave Processes

Bagging film is critical to the success of manufacturing parts with closed molding, vacuum bagging, and out-of-autoclave processes. At Aerovac, we offer a comprehensive range of bagging film products with features such as welded wide format or tailored shapes to reduce labor costs.

The Aerovac range of high-performance bagging films ensure precision, quality and efficiency. Our bagging films are available as roll stock or as engineered kits.

Aerovac Bagging Films are high quality, accessible, easy to customize and supported by experienced technical experts. From global facility locations, Aerovac’s research and development capability is focused on unique customer solutions. Whether it’s humidity resistance or tailored formatting to reduce labor costs, your needs are our priority.

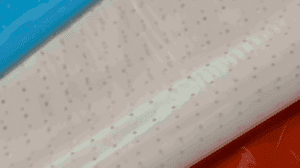

Our Quickdraw films are embossed to eliminate the need for breather when debulking.

Aerovac Bagging Films are available through Composites One in North America, or globally through the Aerovac Distributor Network.

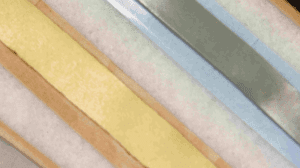

Bagging Film Product List

For more detailed information on each product, fill out the form below to download the respective Technical Data Sheets.

Product

Temp. °F(°C)

Description

VACFILM™205B

248° (120°)

Co-extruded film that is ideally suited to the wind energy and marine markets. Developed for improved handling and performance across a wide range of climates, including cold and dry conditions.

VACFILM™300R

320° (160°)

Red co-extruded film developed for use with prepreg during fabrication of hollow structures up to 320°F (160°C).

VACFILM™430

240° (120°)

Clear high elongation film ideal for de-bulking applications and oven curing up to 248°F (120°C).

VACFILM™400Y

302° (150°)

Yellow high strength, high elongation film for medium temperature applications up to 302°F (150°C), such as the production of large wind energy and marine components.

VACFILM™465B

329° (165°)

Blue tough co-extruded film ideal for use in production of large wind energy components with medium temperature epoxy prepregs up to 329°F (165°C).

VACFILM™200G

248° (120°)

Green co-extruded film ideal for wet lay up and infusion processes up to 248°F (120°C) such as marine and wind energy, compatible with most resin systems.

VB-3

600° (315°)

Beige cast PTFE film with high elongation at elevated temperatures, up to 600°F (315°C) and a chemical etch on one side to ensure good adhesion.

VACFILM® 700R

302° (150°)

Coextruded multilayer film with asymmetric structure that is Ideal for thermoforming, especially where self release characteristics may be required. It is useful as a bladder material for hollow parts and can be used for cures up to 150°C (302°F) temperature.

VACFILM™ 800G

400° (204°)

Green multi-layer extruded film ideal for high temperature curing of aerospace composites, including some BMIs, up to 400°F (204°C).

VACFILM™ 850G

351° (177°)

Highly conformable, transparent, co-polymer film which will remain soft and pliable during cures up to 177°C (351°F). Suitable for use with complex tooling geometry.

VACFILM™ 450V

338° (170°)

Violet, tough but flexible co-extruded film ideal for use with medium temperature epoxy and phenolic prepregs up to 338°F (170°C).

STRETCH-VAC™ 250

250° (121°)

Highly conformable co-polymer film that will remain soft and pliable in cures up to 135°C/275°F. Ideally suited to debulking and hot compaction applications.

STRETCH-VAC™350

350° (177°)

Clear co-polymer film ideal for use with complex tooling geometry up to 350°F (177°C).

STRETCH-VAC™3000

400° (204°)

Pink multi-layer film ideal for high temperature autoclave cures of aerospace composites, including some BMIs, up to 400°F (204°C).

STRETCH-VAC™2000

400° (204°)

Pink multi-layer film ideal for high temperature autoclave cures of aerospace composites, up to 400°F (204°C).

STRETCH-VAC® 4000

414° (212°)

High strength, high elongation mononylon vacuum bagging film rated up to 212°C/414°F. Ideally suited to aerospace and autoclave applications.

STRETCH-VAC™6000

419° (215°)

Heat stabilized film with high elongation, suitable for high temperature (up to 419°F/215°C) autoclave curing of aerospace composites, including BMIs and for applications where softness is required.

VAC-PAK® HS 800

375° (191°)

Gold, co-extruded PA film which is ideal for high temperature/pressure applications where softness and workability are essential, suitable for use up to 375°F (191°C).

VAC-PAK® HS 8171 6/66

400° (204°)

Light blue-green, PA co-polymer film which remains pliable after extended cure cycles. Ideal for advanced composite fabrication and other high temperature/pressure cures up to 400°F (204°C).

VAC-PAK® HS8171

400° (204°)

Clear green, modified nylon film, tough with high elongation. Approved on various aerospace specifications for use up to 400°F (204°C).

QUICKDRAW® HS8171

400° (204°)

Unique film, embossed to allow air evacuation in compaction or de-bulk vacuum bagging processes, without the need for breather fabric or release film.

VAC-PAK® HS6262

450° (232°)

Blue, modified nylon film with excellent elongation and heat ageing properties for use up to 450°F (232°C), approved on various aerospace specifications.

VAC-PAK® HT 620

620° (326°)

Olive colored, high elongation film produced from PTFE resin with a chemically conditioned side to ensure good adhesion for use up to 620°F (326°C).

VAC-PAK® UHT 750

800° (426°)

Amber polyimide film developed for use with high temperature thermoplastic matrix materials up to 800°F (426°C).

POLYIFILM

725° (400°)

Amber polyimide film developed for use with high temperature thermoplastic matrix materials up to 752°F (400°C).

STRETCH-VAC™ PRO-RAP

250° (121°)

Co-polymer low temperature film which can be used for cures up to 250°F (121°C) whilst remaining soft and pliable. Engineered for use with most commonly used resin systems including phenolics.

Understanding Vacuum Bagging and Out-of-Autoclave Processes

The vacuum bagging process is one of the most popular processes for composites manufacturing. It involves using a vacuum bag to surround composite materials in a mold and compress them to ensure optimal resin infusion. Out-of-autoclave processes also involve the use of vacuum and pressure to achieve the desired infusion, but use methods other than placing the bagged mold into an autoclave, such as vacuum-assisted resin transfer molding or pressurized ovens

These processes are critical for modern composite manufacturing because they improve the overall quality of the laminate by ensuring optimal resin distribution and reducing the number of voids created by air pockets.

How Bagging Film Supports Closed Molding

The use of vacuum bagging film is critical for closed molding processes in composite manufacturing. By enveloping the entire mold and creating a tight seal around it, air can be removed from the inside. This means the film compresses the composites under intense pressure, ensuring a tighter bond between all the materials and eliminating any pockets of air that could create voids that weaken the overall structure.

Our lineup of process materials helps manufacturers ensure the highest levels of quality in their composite products. Aerovac vacuum bagging supplies deliver superior performance due to the strength and durability of the materials used which help prevent leaks and support a wide range of temperatures and pressures.

Why Choose Aerovac?

As the second-largest supplier of process materials in the world, Aerovac is a superior source for high-quality vacuum bagging supplies to support vacuum infusion and similar composites manufacturing processes. Aerovac is part of the Composites One family, which means customers have access to industry-leading product knowledge and process support. Our network of distributors around the world means we can provide fast and convenient sourcing to customers worldwide. Customers can rely on Aerovac products to be delivered on-time, competitively priced, and supported by more than 100 technical product experts around the world.

To learn more about Aerovac vacuum bagging products, contact our Team today.