Aerospace Composite Manufacturing Company

Cutting Edge Products for Aerospace Manufacturing

Aerovac delivers high-performance aerospace composites products and process material kits to manufacturers while maintaining cost savings. Aerospace composites manufacturing processes include prepreg processing, vacuum infusion, glass lamination, and others. Aerovac combines high-quality vacuum bagging and process materials, with industry leading technical support to help aviation manufacturers reach their goals. We offer:

- Material management solutions

- Full product line availability

- Many specifications in place

- Focused technical experts

- Customized kits

- Local and expanded logistic solutions in North America

- Dependable service

Global Certifications

Aerovac is positioned to service the aerospace market with required certifications including the AS9120B certification. This is the Quality Management Standard specific to military, defense, and aerospace for distributors. Maintaining this high level of certification ensures manufactures can feel especially confident in a partnership with Aerovac.

These certifications in addition to freezer capacity and a privately owned fleet of delivery trucks, ensures customers can trust in reliable and safe storage of products and reduced lead times.

AS9210B

AS9100

EN9100

SO 9001

Why Aerovac for Aviation?

Aerospace and aviation industries operate on the cutting-edge of advanced composites, demanding high-performance products that are lightweight and high strength. Aerovac offers all the necessary vacuum bagging and process materials for the manufacture of composite aerospace and aircraft components including general aviation, commercial aircraft, military aircraft, and spacecraft applications. Our full range of aerospace composite materials include those for high-temperature cure epoxy, cyanate ester and BMI composites matrices. The legacy of Aerovac Process Materials in addition to the depth and breadth of the Composites One product line combine perfectly to ensure aviation manufacturers consistently produce quality parts.

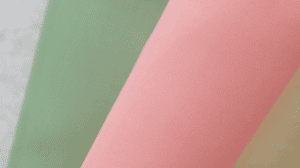

BAGGING FILM

Bagging film products are critical to the success of manufacturing parts with closed molding, vacuum bagging, and out-of-autoclave processes. At Aerovac, we offer a comprehensive range of bagging film products with features such as welded wide format or tailored shapes to reduce labor costs.

RELEASE FILM

Release film products are specially formulated to suit a variety of individual composite process applications. Perforation capability allows the manufacturer to tightly control a variety of perforations including traditional pin-prick, hot needle, and punched, in a comprehensive range of patterns. Release film can also be slit to width, or cut to shape.

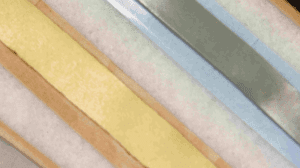

BREATHER FABRIC

Breather fabric is a non-woven polyester or nylon fabric that is designed to allow airflow throughout the vacuum bagging process as well as bleed out excess resin in a composite part. It allows great conformity around a composite part while under vacuum pressure. Aerovac manufactures breather fabric in standard roll formats, slit widths, or cut shapes tailored to meet specific requirements.

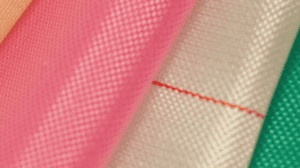

PEEL PLY

Aerovac peel ply products are available in multiple materials and formats to offer flexibility and to match application requirements. Light to heavyweight woven fabrics are available in both nylon and polyester, and some are also available with adhesive backing in order to simplify the consumable application process. Peel ply is available in standard formats, slit widths and cut to shape formats.

RELEASE FABRIC

Systems vary in resin and cure temperature requirements. To satisfy specific application requirements, Aerovac makes light to heavyweight woven fabrics in nylon, glass and polyester, with silicone and fluoropolymer coatings. Release fabric is available in standard formats, slit widths and cut to shape.

SEALANT TAPE

Aerovac offers a comprehensive range of sealant tapes that have been tried and tested in many different and challenging manufacturing environments. Our tapes have been specially formulated to suit a range of cure temperatures, from ambient cures to high temperature thermoplastic cures of 400°C to meet your requirements. Various weights are available.

Key Innovations in Composite Manufacturing

Great strides have been made in recent years when it comes to the aerospace composites market. New techniques and technologies are giving manufacturers greater design flexibility, more durability in components and higher degrees of sustainability. For example, the development of ceramic matrix composites has helped aerospace manufacturers create jet engine parts and other elements that are much better at resisting extreme heat. Another developing innovation is the creation of magnetic polymer nanocomposites, which are being used in research applications to make materials that are highly effective at shielding against electromagnetic interference. The addition of Kevlar to aerospace composite tooling also has helped these materials become stronger and more resistant to impact and abrasive forces.

Aerospace composite manufacturers also are leveraging the power of new technology to enhance and improve their processes. These include additive manufacturing, which uses 3D printing to create parts without generating the same amount of waste as subtractive manufacturing. Other sustainability efforts are leading to new composites that are less harmful to the environment, as well. Many companies also are excited by the potential of artificial intelligence in terms of researching and developing new materials that could bring further improvements to the industry.

Challenges in Aerospace Composite Manufacturing

At the same time as these exciting developments, the aerospace composites market also has to contend with numerous challenges that require new processes and innovative ideas to overcome. For instance, supply chain disruptions continue to reverberate throughout the global market, and certain materials may be in high demand. Many aerospace composite companies also report facing a lack of skilled workers, with many young people choosing instead to seek jobs in the tech industry.

Compliance continues to be a major concern for the industry, as regulations surrounding the creation and use of composite materials tighten in various parts of the world. This is exacerbated by the rapid development of technology, which disrupts the regulatory landscape with each new innovation. As the aerospace composites industry looks ahead to the future, it’s clear that it cannot remain locked into the old ways of doing things. Aerovac stands ready to help our customers keep up with the changes and find forward-thinking solutions to their main challenges. With products that represent the leading edge of composite manufacturing, we are the best choice for composite process materials that provide manufacturers with what they need now and help them prepare for the future.