Vac-Ply Combi 1

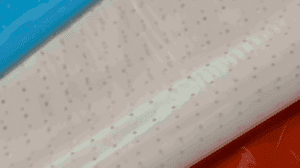

Vac-Ply Combi 1 is an innovative combination product of perforated release film, knitted infusion mesh, and peel ply designed for vacuum infusion applications. This combination peel ply release film reduces lay-up time and complexity, and is more conformable than cast grid meshes. Our peel ply and release film also strips easily and cleanly from the laminate surface due to its excellent release properties. Removal after cure can be done in two ways: either all three layers or just the release film and mesh, leaving the peel ply as temporary protection for the laminate surface.

FEATURES OF VAC-PLY COMBI 1

- Perforated release film combined with knitted infusion mesh and peel ply.

- Strips after cure in two ways. Either all three layers together or just the release film and mesh leaving the peel ply as temporary protection for the laminate surface.

- Reduces layup time and complexity.

- More conformable than traditional cast grid meshes.

- Easily tailored to complex parts.

Max Use Temperature

120°C (248°F)

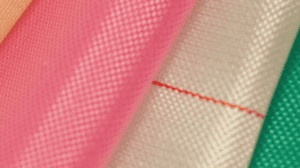

Color

Blue mesh, red release film and white with pin stripes peel ply.

Fiber

Polyethylene (PE) and Nylon (PA)

Weight

235g/m² | 6.93oz/yd²

UNDERSTANDING THE TERMINOLOGY

Our combination peel ply release film consists of three layers:

- Perforated release film — This is designed to make pulling materials from your setup after completion easier.

- Knitted infusion mesh — This material allows the composite materials to flow more effectively into place, especially when it comes to complex molds.

- Peel ply — Once the part is cured, the peel ply layer ensures it can be removed from the bagging system without complications.

STORAGE, HEALTH & SAFETY

No special storage conditions are required, however, we recommend this peel ply and release film be stored in its original packaging. Please refer to the product SDS for safe handling, personal protective equipment recommendations, and disposal considerations.

If you would like to request a quote for additional products, please utilize our main Quote Request Form.

DISCLAIMER: The data and information provided on this page have been obtained from carefully controlled samples and are considered to be representative of the product described. Aerovac does not express or imply any guarantee or warranty of any kind including, but not limited to, the accuracy, the completeness or the relevance of the data and information set out herein. Because the properties of this product can be significantly affected by the fabrication and testing techniques employed, and since Aerovac does not control the conditions under which its products are tested and used, Aerovac cannot guarantee the properties provided will be obtained with other processes and equipment. No guarantee or warranty is provided if the product is adapted for a specific use or purpose. Aerovac declines any liability with respect to the use made by any third party of the data and information contained herein. Aerovac has the right to change any data or information when deemed appropriate. All trademarks are the property of their respective owners. ©2023 Aerovac LLC. All rights reserved.