Vac-Ply VMS3

Vac-Ply VMS3 is a revolutionary vacuum medium strip, which opens new possibilities in infusion network design. These vacuum infusion materials reduce the risk of dry spots or incomplete wet out by drawing air and volatiles from the laminate throughout the infusion process, minimizing resin being drawn into the vacuum line. The infusion network can be simplified, with a significant reduction in the number of vacuum connectors required. VMS3 also reduces the risk of rework and resin waste, as well as optimizing process control and part quality.

FEATURES OF VAC-PLY VMS3

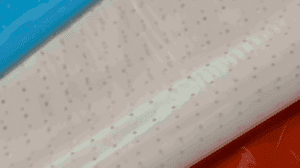

- Microporous vacuum line suitable for vacuum infusion and prepreg processing.

- Multilayers designed to maximize air removal during infusion and cure.

- Optimizes impregnation and avoids dry spots during infusion.

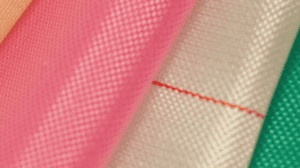

- Multi-colored vacuum line aids correct orientation.

Max Use Temperature

80°C (176°F) during infusion. Withstands an exothermic peak of 140°C (285°F).

Color

Orange on release side, white on outer side.

Format

Available with micro-perforated release film as standard. Peel ply or Teflon coated available on request.

Widths

100 meters rolls in 100, 150 and 300 mm width.

No special storage conditions are required — however, we recommend these vacuum infusion supplies be stored in their original packaging. Please refer to the product SDS for safe handling, personal protective equipment recommendations and disposal considerations.

If you would like to request a quote for additional products, please utilize our main Quote Request Form.

DISCLAIMER: The data and information provided on this page have been obtained from carefully controlled samples and are considered to be representative of the product described. Aerovac does not express or imply any guarantee or warranty of any kind including, but not limited to, the accuracy, the completeness or the relevance of the data and information set out herein. Because the properties of this product can be significantly affected by the fabrication and testing techniques employed, and since Aerovac does not control the conditions under which its products are tested and used, Aerovac cannot guarantee the properties provided will be obtained with other processes and equipment. No guarantee or warranty is provided if the product is adapted for a specific use or purpose. Aerovac declines any liability with respect to the use made by any third party of the data and information contained herein. Aerovac has the right to change any data or information when deemed appropriate. All trademarks are the property of their respective owners. ©2023 Aerovac LLC. All rights reserved.