Tooling

Home > Tooling

Innovative Tooling Solutions

Aerovac is a major manufacturer, developer and supplier of tooling used in prepreg processing, vacuum infusion, glass lamination and other industrial applications. As part of Composites One, we’re uniquely positioned to provide customers with next-gen product and supply chain innovations that are stored locally, priced competitively, delivered on-time and supported by more than 100 technical product experts worldwide.

Aerovac’s tooling expertise is unparalleled. For more than three decades, our innovative tooling and technologies meet or exceed our customers’ needs. Our confidential design and engineering service helps our customers develop their tooling projects from initial concept to prototyping and production.

Our comprehensive range of tooling solutions include:

- Tooling prepregs for all markets (unidirectional and fabric, using carbon and glass fibers)

- Vacuum bagging consumables (for low and high temperatures)

- Tooling blocks, backing structures, sealing systems and ancillaries

- Tooling hardware including composite tools and reusable silicone tools

- Worldwide manufacturing, design and technical support backed by our commitment to satisfy short lead times

Composites Tooling Solutions

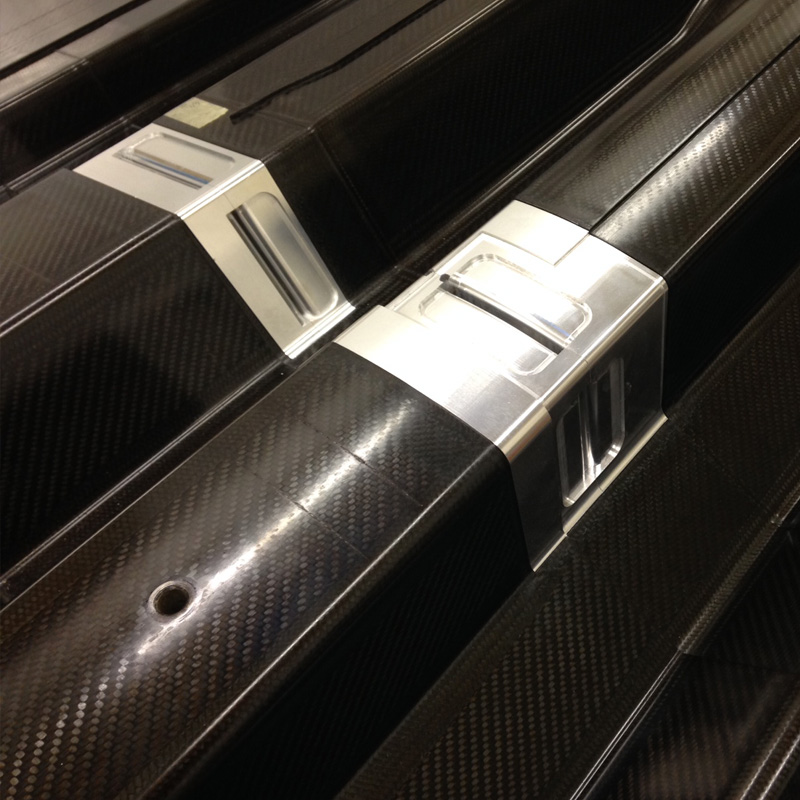

Aerovac introduces a new level of performance to the design and manufacture of high-quality composite tooling. Composites are often used for tooling, allowing the coefficient of thermal expansion (CTE) match between tooling and the composites parts being produced which enables the manufacture of more precise parts.

Our Toulouse, France facility, with its range of autoclave equipment, naturally specializes in utilizing glass epoxy, carbon epoxy or BMI carbon fibers to produce large tooling with tight geometric tolerances. From inexpensive masters, molds are duplicated at minimal cost to be mounted on adjustable frames or carbon couplings.

Aerovac solutions include:

- Composite lay-up molds

- Assembly works stations

- Drilling support mold

- Caul Plate

Why Composite Tools?

- Lightweight and reusable

- Good for complex geometries

- Can be processed at low temperatures

- Offer good mechanical performance and durability

- Excellent surface finish

- Allows for CTE match between tool and composites parts being produced

Silicone Tooling Solutions

Aerovac offers one of the most advanced lines of reusable vacuum systems, manufacturing techniques and sealing systems in the industry, including:

Reusable membranes for high temperature autoclave and out-of-autoclave applications

- Increase productivity, reduce operating costs and minimize waste

- Easily applied to complex forms for high volume production of quality parts

- Durable construction to eliminate tearing during curing

- Include seal systems fitted on elastomeric tools to provide vacuum integrity and accommodate complex shapes

Heated flat mats and vacuuming membranes for hot bonding or on-site repairs

- Can be molded to shape

- Have a frame or ceiling skirt to ensure vacuum integrity; no additional consumables needed

IMS (Infusion Membrane Silicone) membranes

- Flexible and precisely molded to the part’s shape, they provide a resin feed network for infusion.

Intensifiers preventing compaction issues on parts

- Transmit vacuum bag pressure evenly to localized, detailed areas on parts with complex angular or concave features

- Made from silicone and fibrous carbon/epoxy reinforcements, providing rigidity and dimensional stability

Why Silicone Tools?

- Increase efficiency and reliability

- Help reduce labor time

- Optimize material flow

- Improve process consistency

- Increase part quality

- Provide cost savings

- Eliminate the time and cost of purchasing, cutting and recycling films

- Seal instantly, preventing resin leakage during infusion

- Provide a smooth surface for infused parts

- Suitable for counter-tools and easy to implement, repair and modify

- Reusable vacuum bag assemblies can be added to tool structures

- Fabricated pre-shaped vacuum bags save time and reduce waste