VACFILM 500G

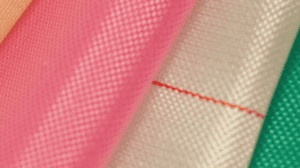

VACFILM 500G is designed for both vacuum bagging and release applications, with release properties on both sides of the film, suitable for cures up to 302°F. It provides reliable release from most resins used in Aerospace, Automotive, and Marine industries.

The embossed version accelerates compaction and debulking, making the process faster and more efficient. Additionally, VACFILM 500G can be perforated with different perforation patterns, as available in the release film portfolio.

FEATURES OF VACFILM 500G

- Designed for both vacuum bagging and release applications on both sides.

- Embossed version available as VacDraw 500G for use in compaction and debulking.

- Capable of withstanding operating temperatures of 150°C (302°F), providing sufficient temperature resistance to withstand most common resin exothermic reactions.

Max Use Temperature

150°C (302°F)

Color

Green

Fiber

Nylon, Polyolefin multilayer

Tensile strength at break (ASTM D882)

50 MPa | 7251 PSI

Elongation at break (ASTM D882)

500 %

Thickness

50 μm and 75 μm | 0.002 in and 0.003 in

Widths

Up to 5 m (2.5 m tube) | Up to 196 in (98 in tube)

Formats available

Sheet, V-sheet and Lay flat tube

Do not store rolls vertically on their ends. Please refer to the product SDS for safe handling, personal protective equipment recommendations and disposal considerations.

EXPLORE MORE FEATURED PRODUCTS

If you would like to request a quote for additional products, please utilize our main Quote Request Form.

DISCLAIMER: The data and information provided on this page have been obtained from carefully controlled samples and are considered to be representative of the product described. Aerovac does not express or imply any guarantee or warranty of any kind including, but not limited to, the accuracy, the completeness or the relevance of the data and information set out herein. Because the properties of this product can be significantly affected by the fabrication and testing techniques employed, and since Aerovac does not control the conditions under which its products are tested and used, Aerovac cannot guarantee the properties provided will be obtained with other processes and equipment. No guarantee or warranty is provided if the product is adapted for a specific use or purpose. Aerovac declines any liability with respect to the use made by any third party of the data and information contained herein. Aerovac has the right to change any data or information when deemed appropriate. All trademarks are the property of their respective owners. ©2023 Aerovac LLC. All rights reserved.